What is vegetable-tanned leather?

Vegetable-tanned leather is leather that has been tanned with tannins derived from natural compounds in tree bark.

Vegetable tanning has been used for centuries and is considered environmentally friendly. It is slower than other tanning processes, benequires over 30 days to transform hides into leather, but does not require chemicals.

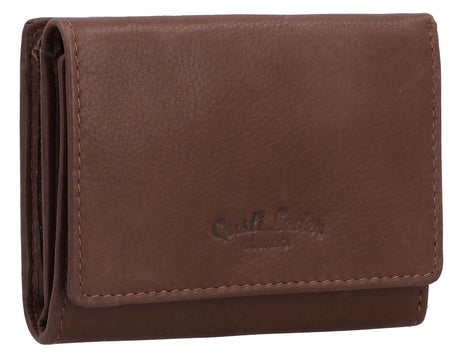

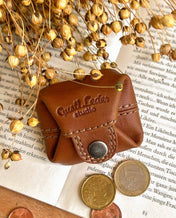

All our products at Gusti Leather are made from vegetable-tanned leather. We have chosen this process because it is less harmful to the environment, produces no toxic waste, and creates strong, durable leather while enhancing the natural colour of the leather.

What is the process of vegetable tanning at Gusti?

At Gusti, we use vegetable-tanned leather from pits. We source our vegetable-tanned leather mainly from two sources:

- Our local tannery buys hides from local butchers.

- They also receive leather scraps that arise during Eid celebrations.

This means that each piece of leather is sourced locally from the surrounding districts.

-

1. The raw hides are salted to preserve them and then sent to the tanneries.

2. The hides are desalted in drums to remove the salt used for preservation.

3. The hides are washed with a solution of lime, sulfur sulfate, and enzymes to remove any hair during the liming process.

4. Excess flesh is removed from the wet hide with a fleshing machine.

5. The hides are now ready to begin the pickling process.

6. The hide is brought back to the tannery, where the tanners wet the hides and layer them in a pit.

7. The hides are stacked on top of each other, with tree bark sprinkled between each hide. Then water is added to the pit.

8. The tree bark, also known as tannin, releases the tanning agent, which is absorbed by the hide. At Gusti, we use bark from the Babul and Aaval trees and avoid the use of chemicals.

9. Once all the tanning agent has been released, the hides are moved to another dry pit, and the process is repeated.

10. The entire process is repeated for 25 to 35 days and is completed once the hide is tanned and has returned to its original form. This process is known as pit tanning of vegetable-tanned leather.

-

11. The excess fat is then removed from the skin by hand.

12. Castor oil is applied to the skin and it is hung up to dry.

13. After drying, any stiffness is removed from the skin with a knife.

The skin is then ready for use.

14. The skin is washed again, dried in the sun, and then made into bags.

This process results in 100% vegetable-tanned goat leather from the pit.

In the production of our vegetable-tanned leather, we adhere to the following standards:

- Our products from Gusti Leder Nature are 100% vegetable-tanned.

- Our products from Gusti Leder Studio contain less than 3000 mg of chromium per kilogram of leather + one of the tanning processes the hides undergo must be a vegetable tanning.

This process results in 100% vegetable-tanned goat leather from the pit.

In the production of our vegetable-tanned leather, we adhere to the following standards:

- Our products from Gusti Leder Nature are 100% vegetable-tanned.

- Our products from Gusti Leder Studio contain less than 3000 mg of chromium per kilogram of leather + one of the tanning processes the hides undergo must be a vegetable tanning.

How do we ensure that the standards are met?

We regularly test our leather products, you can see which products have been tested on our product pages.

If we find that three chromium-free products have a chromium content of more than 1000mg, we impose a penalty equivalent to 40% of the shipment's value.

Is vegetable-tanned leather better for the environment?

Vegetable tanning is considered a benchmark in the leather industry because it causes less environmental pollution.

Advantages:

Environmentally friendly: The vegetable tanning process uses purely organic materials like tannins from tree bark and produces no toxic waste.

Biodegradability: Vegetable-tanned leather is highly biodegradable and decomposes gradually without harming the environment.

Unique appearance and color: Vegetable tanning produces strong and durable leather. The natural color of the leather enhances its authentic character.

Sustainability: The technique of vegetable tanning supports sustainable practices and does not use chemical substances that could have negative effects on the environment.

Health benefits: Vegetable-tanned leather is not treated with harmful chemicals like chromium, so it does not cause allergic reactions or skin irritations when you come into contact with it.

Is vegetable-tanned leather better for the environment?

Compared to other tanning methods, such as chrome tanning, vegetable tanning is a more sustainable way of leather processing.

Through this tanning process, we avoid the use of chemicals and create high-quality, durable leather. Vegetable tanning improves the durability and appearance of the leather while maintaining its breathability and comfort.

Join the slow fashion movement, make more conscious choices, and discover our bags and accessories made from vegetable-tanned leather.